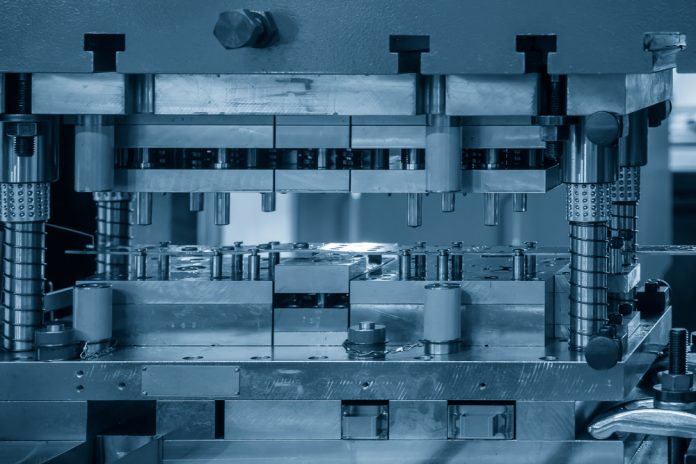

As the precision stamping parts come out of the presses, they are covered with things like lubricants, metal shavings, and dust. These contaminants could affect how the part works, so they have to be taken out before it can go to the next step, like metal finishing or welding, or go straight to the production line.

Most metal stampers offer a range of cleaning services in-house, but for specialised cleaning services, they may call on other approved suppliers. In some cases, the metal may need to be cleaned more than once, both after it has been stamped and again after it has been finished, to make sure it works well.

How to Get the Lubricant off Precision Stamping Parts

Use a Solvent

Solvents are the most common way to get rid of stamping lubricant. There are many on the market, so you need to find the best one. Read the labels carefully and do what they say to keep safe. When using solvents, you should wear the proper safety gear, like gloves and goggles.

Use the solvent to wet a cloth and wipe the lubricant off the metal parts. To keep the part from getting damaged, you should always put the solvent on the cloth and never on the part itself. After using a solvent to clean the stamping part, it should be rinsed with clean water and soap, as needed, to eliminate any leftover lubricant on the part’s surface.

Solvents are an excellent way to clean lubricant off metal stamping parts because they don’t hurt the part.

Clean With a Cleaner

Many kinds of cleaners can be used to get stamping lubricant off of metal parts. But before using it, ensure it works with the metal you are cleaning. If you use the wrong cleaner, rust or other damage could happen to the finish. Then put it on the dirty area and clean it with a cloth. Repeat the process until all the surface dirt has been taken care of.

Use Sandpaper

You can get rid of stamping lubricant with paper towels and sandpaper. Soak the sandpaper in water and wrap it around a ball of towel. Keeping the part in place while you clean it requires holding onto both ends of the towel. Rubber gloves can help keep you from getting fingerprints on things. The method needs practice, but in some situations, it works better than other methods. The surface of precision stamping parts can be harmed by using solvents or cleaning solutions.

Cleaning the stamping component with sandpaper or re-wipes is an efficient approach to getting rid of dirt without hurting it. Sandpaper is also great for getting rid of stains.

Use Ammonia

Ammonia is an excellent choice for the environment. Just put some on a cloth and wipe the item clean. When using ammonia, you should wear gloves and goggles and try not to get it on your skin or your eyes.

Ammonia is a safe cleaner for the environment and can be used to get oil and grease off metal parts.

Conclusion

To choose the proper cleaning process, you need to know the type of metal, how solid or fragile the stamping is, how big it is, how clean it needs to be, and what kind of metal finishing will come after stamping. Also, many manufacturers follow the rules about the environment that say they can’t use certain cleaning solvents. Engineers with metal stamping can advise on the cleaning and finishing options that will work best for the precision stamping parts and meet industry quality standards.